Grease Trap 101: History

In the world of restaurants today, a vague and ambiguous piece of equipment is being required by health inspectors everywhere. Some businesses, which have been in business for 20 years, are suddenly being required to install these in their stores. What are they?

In the world of restaurants today, a vague and ambiguous piece of equipment is being required by health inspectors everywhere. Some businesses, which have been in business for 20 years, are suddenly being required to install these in their stores. What are they? Do we really need one? What size do I need? How do I install them?

History Lesson: The grease trap concept was originally patented in the early 1800s by Nathaniel Whiting in CA. The basic design of his grease trap and the grease traps sold and used today have not really changed. Due to build up of fats, oils and grease (FOG) in sewer lines and septic systems, grease traps are needed to keep FOG from settling and causing blockages. In the 1940s, the Plumbing and Drainage Institute (PDI) began developing ratings for capacity and flow rates. The most common grease trap will meet the PDI-G101 requirements.

What is a grease trap? A grease trap is a unit which separates the FOG from the water and stores the FOG to keep it from entering into the drainage line and sewer systems.

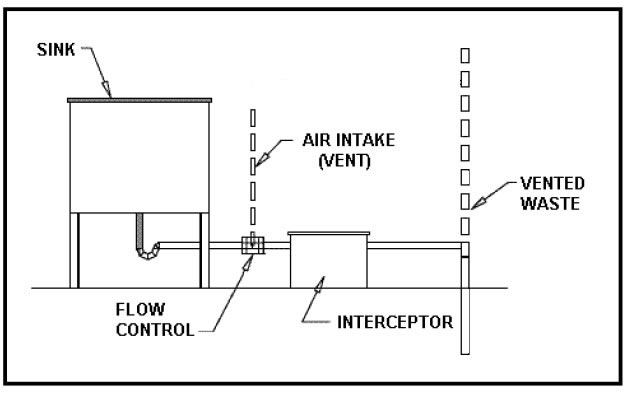

How does a grease trap work? A standard grease will slow down hot water containing FOG. Since FOG is approx 80% lighter than water, once the water is cooled, they will separate from the water and remain trapped by the baffle inside the grease trap allowing only water to exit the grease trap into the sewer lines. Below is the basic set up for manual grease traps.

To read more about the types of grease traps,

click here: Grease

Trap 101: Types.

To read more about the sizing of grease traps, click here: Grease Trap 101:

Sizing.